In decreasing the number of satellites on the dropwatcher, you actually turned all the drops into satellites in production. The turbulent air inside the system blew them off course before they were able to land in the proper positions. When you started printing in production, the slower drops no longer had enough momentum to cover the distance between the printhead and the substrate. Unknowingly, when you made your changes that decreased the number of satellites, you also decreased the drop velocity by a small amount. Pleased with these results, you continue forward to working on another aspect of the project. After a few days, you are able to produce drops that have fewer satellites with no noticeable change in sustainability over time.

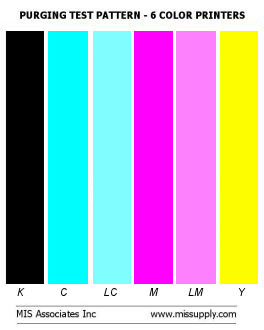

Using what you’ve learned in our post How to Stop Satellites from Ruining Your Print, you spend some time adjusting the ink formulation and the waveform. Using a dropwatcher, you’ve noticed that your jetting tends to produce some satellite droplets and you want to see if you can eliminate them. To help explain why periodically taking a step back and evaluating the system as a whole is important, consider the following example. We believe that all of these individual tweaks and improvements around the system should result in a better printed product, but how can we take a big picture view and see this? In this article, we will discuss how to evaluate printing performance as a whole, using print quality analysis. We’ve discussed comparing waveforms by studying drop formation and velocity, improving latency by adding a tickle pulse, and determining whether or not to use degassing by measuring dissolved oxygen.

To date, most of our articles have been focused on evaluating individual aspects of the printing process.

0 kommentar(er)

0 kommentar(er)